Welcome to the website of Jiangsu Jiuyuan Power Equipment Co., Ltd

Welcome to the website of Jiangsu Jiuyuan Power Equipment Co., Ltd

2024-11-24

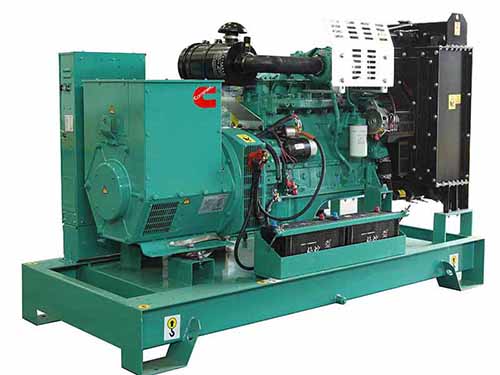

Open type industrial diesel generator sets refer to power generation systems where the engine and alternator are not enclosed in a soundproof canopy. These units are typically used in industries that require robust power supply solutions, but where noise and weather protection are less of a concern. Unlike their silent or enclosed counterparts, open type generators are generally more affordable and easier to maintain. They are also known for their durability and high performance in extreme environments.

Open type industrial diesel generators, with proper maintenance, can last anywhere from 10,000 to 30,000 hours of operation. The lifespan depends on various factors including the quality of the diesel engine, the load on the generator, and how well the unit is maintained. Regular servicing such as oil changes, fuel filtration, and cooling system checks can significantly extend the life of the generator. Regular monitoring and early repairs can also prevent major engine issues.

The cost of an open type industrial diesel generator set can vary widely depending on factors such as the power rating (measured in kilowatts), the manufacturer, and additional features. On average, prices range from $5,000 to $40,000 USD. Larger generators with higher power outputs will naturally cost more. It’s important to factor in long-term costs such as fuel consumption, maintenance, and potential repairs when calculating the total cost of ownership.

To ensure the optimal performance of open type industrial diesel generators, it is recommended to use the following tools for maintenance oil filters, fuel filters, multimeter for electrical testing, temperature sensors, and cooling system diagnostics tools. Additionally, regularly check the exhaust system and ensure the generator’s wiring and battery are in good condition. Using proper maintenance tools ensures minimal downtime and better performance during critical power supply periods.

When installing an open type industrial diesel generator, the most important factor is ensuring proper ventilation and accessibility for regular maintenance. The installation location should be dry and well-ventilated, away from flammable materials and excessive dustdiesel dc generator set. The generator should be placed on a stable foundation to minimize vibrations and wear. It is also crucial to connect the unit to an appropriate fuel source and ensure electrical wiring is compliant with local regulations. professional installation team is recommended for safety and efficiency.

Routine maintenance for an open type industrial diesel generator involves several key tasks. First, check the oil level and replace the oil every 250-500 hours of operation. Clean or replace fuel filters and air filters to prevent clogging. Ensure that the cooling system is functioning properly by inspecting coolant levels and cleaning radiator fins. Conduct a load test to verify the generator’s performance under different operational conditions. It’s also important to check the battery charge and condition regularly.

Open type diesel generators offer several advantages for industrial usediesel generating sets manufacturers. They are generally less expensive than enclosed generator sets, making them a cost-effective choice for businesses looking for reliable power solutions. These units are more accessible for maintenance and repairs due to their open design. They also tend to have a longer service life because of their ability to run efficiently without the constraints of an enclosed space. For industries operating in environments where noise is not a major concern, open type generators are ideal.

Open type industrial diesel generators are capable of handling a wide range of loads, from small industrial operations to large-scale manufacturing plants. The generator’s load capacity is directly related to its power rating, which can range from a few kilowatts to several megawatts. These generators can be used for both continuous power supply and backup power applications. Additionally, open type generators can be equipped with automatic transfer switches (ATS) for seamless load management during power interruptions.

Optimizing the performance of an open type industrial diesel generator involves regular maintenance, proper installation, and load management. Ensure the generator is operating within its optimal load range to prevent overloading or underloading, both of which can lead to inefficiency and wear. Use high-quality fuel and lubricants to improve engine performance and longevity. Additionally, performing load testing on a regular basis helps to identify potential issues early and keeps the system running at its best.

The primary difference between open type and enclosed industrial diesel generators lies in their design and application. Open type generators are typically used in settings where noise and environmental factors are less of a concern. They are more cost-effective and easier to maintain because of their open designmanufacturing diesel generator sets. On the other hand, enclosed generators feature a canopy or casing that helps reduce noise levels and provides protection against the elements, making them more suitable for environments that require a quieter or more weatherproof solution. However, enclosed generators tend to be more expensive and may require additional maintenance due to their complex design.