Welcome to the website of Jiangsu Jiuyuan Power Equipment Co., Ltd

Welcome to the website of Jiangsu Jiuyuan Power Equipment Co., Ltd

2024-11-25

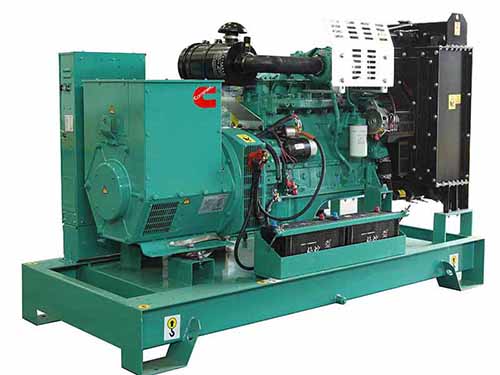

The Diesel Generator Set QSB7 Cummins is a highly efficient, reliable, and powerful engine system specifically designed for a variety of applications, including power generation. Powered by Cummins’ QSB7 engine, this generator set offers superior performance, enhanced fuel efficiency, and robust durability, making it an ideal solution for both industrial and commercial use.

Diesel Generator Set QSB7 Cummins typically lasts between 10,000 to 20,000 hours of operation, depending on factors like maintenance, usage conditions, and operational environment. Proper maintenance and timely servicing can significantly extend the lifespan of the generator set, ensuring it remains reliable for years to come.

The cost of a Diesel Generator Set QSB7 Cummins varies based on its configuration, output capacity, and additional features. On average, the price ranges from $10,000 to $30,000. Factors like customizations, shipping, and installation services also influence the overall costdiesel engine driven multi process welding set and generator. For precise pricing, it is recommended to contact a certified Cummins distributor or supplier.

Maintaining a Diesel Generator Set QSB7 Cummins requires specific tools and equipment to ensure its longevity and performance. Key tools include a digital multimeter for electrical diagnostics, a torque wrench for tightening bolts, and fuel system cleaning tools for maintaining fuel injectors. Additionally, using Cummins-approved lubricants and filters is critical for ensuring engine health and efficiency.

During an emergency, handling a Diesel Generator Set QSB7 Cummins involves quickly assessing the situation to ensure the generator is in safe working condition. Prioritize checking fuel levels, coolant temperature, and oil pressurechina diesel generator set 60kw. If the generator fails to start or experiences irregularities, it is important to consult the generator’s user manual or contact a certified technician for troubleshooting.

Proper maintenance of the Diesel Generator Set QSB7 Cummins involves a few critical steps regularly changing the oil, replacing air and fuel filters, checking and cleaning the cooling system, and inspecting the exhaust system. Additionally, perform load bank testing periodically to verify the generator’s performance under load. Following the manufacturer’s maintenance schedule ensures optimal performance and helps prevent unexpected breakdowns.

The Diesel Generator Set QSB7 Cummins offers several advantages over other generator sets. First, its fuel efficiency is outstanding, thanks to Cummins’ advanced engine technology. The engine is also known for its low emissions, making it an eco-friendly option. Furthermore, Cummins offers excellent after-sales service and a wide network of service centers, ensuring that any issues are addressed promptly and effectively.

The Diesel Generator Set QSB7 Cummins is available in various configurations, including different power outputs, cooling options, and enclosures. It is offered in both open and soundproofed models, with power outputs typically ranging from 150 kVto 200 kVA. The generator set can be customized based on specific customer requirements, such as including automatic transfer switches or parallel operation capabilities for greater flexibility.

Common issues with the Diesel Generator Set QSB7 Cummins include fuel system blockages, battery failure, or problems with the cooling systemcaterpillar 400 kw diesel generator set. To resolve these issues, ensure regular inspection and cleaning of fuel injectors, replace batteries as needed, and check the coolant levels frequently. If any issue persists, it is advisable to contact a certified Cummins service center for professional diagnosis and repair.

To optimize your Diesel Generator Set QSB7 Cummins for long-term performance, you must follow a few key practices. Regularly change the oil and filters, monitor engine performance through diagnostic tools, and ensure that the generator is operated within its recommended load capacity. Moreover, implementing a comprehensive monitoring system will allow for real-time performance tracking and early identification of potential issues.