Welcome to the website of Jiangsu Jiuyuan Power Equipment Co., Ltd

Welcome to the website of Jiangsu Jiuyuan Power Equipment Co., Ltd

2024-11-21

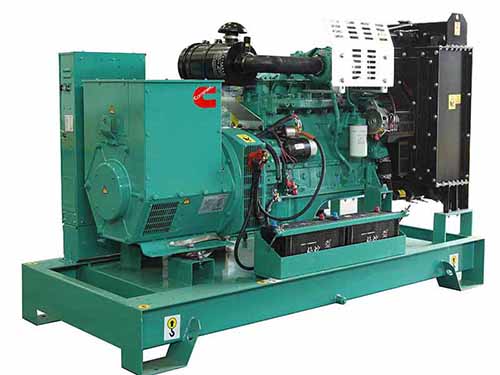

Diesel Engine Generator Set – Diesel Generator Sets for Commercial and Industrial Applications

diesel engine generator set (DG set) is a combination of a diesel engine and an electric generator, commonly used to provide power for commercial, industrial, and residential applications. These generator sets are highly reliable and are designed to operate in remote locations or during power outages. Diesel engines are often preferred because of their efficiency and long-lasting performance in various environments.

The lifespan of a diesel engine generator set depends on factors such as maintenance, usage, and operating conditions. On average, a well-maintained diesel generator can last between 10 to 30 years. However, regular servicing, proper fuel management, and avoiding overloading can extend its lifespan significantly. Routine inspections are essential to ensure the longevity of the generator set and to avoid costly repairs.

The cost of a diesel engine generator set varies depending on its power output, brand, and features. Small portable units can start from around $1,500, while larger, industrial-grade units can cost between $10,000 to $50,000 or more. Additional costs include installation, maintenance, and fuel consumption. For industrial applications, a high-quality diesel generator set may come with advanced features like noise reduction, remote monitoring, and automatic start/stop systems, which can further increase the price.

Managing a diesel engine generator set requires specialized tools for monitoring performance, fuel usage, and maintenance schedules. Tools like generator monitoring systems and fuel management systems can help track the generator’s efficiency and ensure that it is operating optimally. Brands such as Caterpillar and Cummins offer proprietary software to monitor generator health, and third-party tools like Fleet Management Software can also assist with tracking usage and service history.500 kva diesel generator set

Proper maintenance of a diesel generator set involves several key practices. Regular oil changes, fuel system cleaning, and air filter replacement are critical to ensure optimal performance. Additionally, it’s important to check the cooling system, inspect the exhaust, and perform load tests periodically. Keeping the battery charged and ensuring proper ventilation are also essential steps. detailed maintenance schedule and the use of high-quality components are important for preventing downtime and enhancing the lifespan of the generator set.cummins onan diesel generator set 50kw-60kw

Load testing is crucial for assessing the diesel generator’s ability to perform under heavy usage and to detect any potential issues before they cause a failure. load test involves running the generator at full capacity for a set period to simulate actual operating conditions. This process helps to ensure the generator’s engine and electrical components are working as expected. It also verifies that the generator is capable of handling the load required in emergency situations. Regular load tests can prevent surprises during critical power outages.

Diesel engine generator sets offer several advantages in industrial settings, such as cost-effectiveness, reliability, and fuel efficiency. They are ideal for continuous or backup power requirements, providing a steady supply of electricity without the need for grid connection. Diesel generators are also more durable and have a higher power-to-weight ratio compared to other fuel types. In industries where power outages can cause significant downtime, a diesel engine generator ensures operational continuity and productivity.

To improve the fuel efficiency of a diesel generator set, it’s important to operate the generator at its optimal load capacitydummy load for diesel generator set. Overloading or running the generator at too low a load can result in inefficient fuel consumption. Regular maintenance, including fuel system cleaning and proper air intake, can also improve fuel efficiency. Additionally, choosing high-quality fuel and avoiding prolonged idling periods can help conserve fuel. Many modern diesel generators come equipped with fuel-saving features like automatic load management and advanced fuel injection systems.muffler 6 caterpillar diesel generator set c9

Common issues with diesel engine generator sets include problems like starting failures, overheating, and poor power output. To troubleshoot starting issues, check the battery, fuel supply, and electrical connections. Overheating can often be caused by insufficient cooling or a dirty radiator. For power issues, inspect the fuel filter and the alternator. Most problems can be resolved with regular maintenance and timely repairs, but if the issue persists, it may be necessary to consult a professional technician. Understanding the generator’s user manual and common fault codes can assist with quick diagnosis.

Although diesel engines have a reputation for producing emissions, modern diesel engine generator sets are designed to meet stringent environmental standards. They are often more fuel-efficient than gasoline generators, producing less waste and consuming less fuel for the same amount of energy. Additionally, diesel generators can be used in remote locations where grid power is unavailable, reducing the need for extensive power line infrastructure. Many generators also feature low emissions technology, contributing to a cleaner and more sustainable energy solution.