Welcome to the website of Jiangsu Jiuyuan Power Equipment Co., Ltd

Welcome to the website of Jiangsu Jiuyuan Power Equipment Co., Ltd

2024-11-25

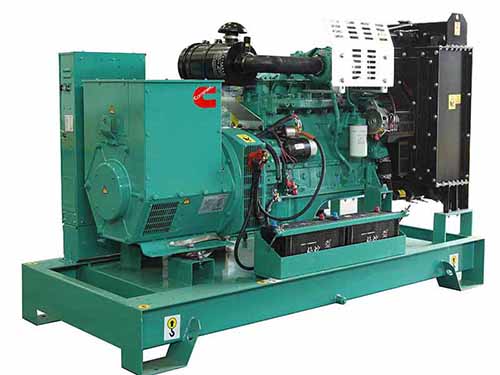

diesel engine for generator set is a type of internal combustion engine that operates using diesel fuel to produce mechanical energy, which is then converted into electrical power. These engines are widely used in both residential and industrial generator sets due to their fuel efficiency, durability, and ability to generate power in remote locationsl84622 generator set diesel. Diesel engines provide an excellent solution for continuous power supply, especially in areas with unreliable electricity grids.

The lifespan of a diesel generator engine largely depends on factors like maintenance, load usage, and operational conditions. On average, a well-maintained diesel engine in a generator set can last between 15,000 to 30,000 hours of operation. Regular servicing, such as oil changes, filter replacements, and cooling system checks, can significantly extend the lifespan of the engine.wholesale weichai diesel generating set

The cost of a diesel engine for a generator set can vary depending on its power output, brand, and specific requirements. Typically, the price for smaller models suitable for home use ranges from $3,000 to $10,000, while larger industrial generators can cost between $20,000 and $100,000 or more. It’s important to consider factors such as fuel consumption, maintenance costs, and overall durability when evaluating the total cost of ownership.

To properly maintain a diesel engine in a generator set, several essential tools are required. Some of the most important include a digital multimeter for diagnosing electrical systems, a fuel pressure gauge for checking fuel system pressure, and a coolant temperature monitor to ensure the engine does not overheat. Regular use of these tools ensures that any potential issues are caught early, preventing costly repairs and downtime.

To optimize the performance of your diesel engine generator set, it is crucial to follow a strict maintenance schedule. This includes regularly checking the oil, fuel, and air filters, ensuring that the cooling system is working properly, and keeping the engine clean from dirt and debris. It’s also essential to run the generator periodically, even if it’s not in regular use, to prevent the engine components from becoming corroded or seized.

Proper installation of a diesel engine for generator set involves several key steps. First, ensure that the installation site is dry, well-ventilated, and level to prevent operational issues. Then, connect the engine to the fuel system, ensuring all connections are secure and free from leaks. Next, install the exhaust system to prevent toxic fumes from building up. Finally, conduct a test run to confirm that the engine is operating correctly and that all safety features are functioning properly.

There are various types of diesel engines for generator sets based on their application and power output. The two main types are air-cooled engines, which are typically used for smaller, portable generators, and water-cooled engines, which are designed for larger, industrial generators that require higher power output and efficiency. Water-cooled engines are more efficient at dissipating heat and are therefore ideal for continuous heavy-duty use.

The use of a diesel engine in a generator set offers numerous advantages. These include greater fuel efficiency, as diesel fuel provides more energy per unit than gasoline. Diesel engines also tend to have a longer lifespan and require less maintenance than gasoline engines. Additionally, they are less flammable, making them a safer choice for industrial settings. Their robust performance makes them ideal for both backup power and continuous operation in remote locations.

To ensure a diesel engine operates efficiently in a generator set, it is essential to monitor its load capacity. Running the engine at or near its rated load for extended periods can reduce fuel consumption and prevent excessive wear and tear. Additionally, keeping the engine properly tuned and maintaining a clean fuel system can help improve efficiency. Regularly checking the exhaust emissions can also provide insight into the engine’s performance and highlight potential issues.

Using tools such as engine monitoring systems or remote diagnostic software can help track the performance of a diesel engine in a generator set. These systems allow for real-time monitoring of key parameters, including fuel consumption, engine temperature, and operating hours. By analyzing this data, you can identify trends and take proactive steps to maintain engine performance. Additionally, using platforms like Google Analytics for website data or SCADsystems for industrial control can also help you stay on top of generator performance metrics.