Welcome to the website of Jiangsu Jiuyuan Power Equipment Co., Ltd

Welcome to the website of Jiangsu Jiuyuan Power Equipment Co., Ltd

2024-11-21

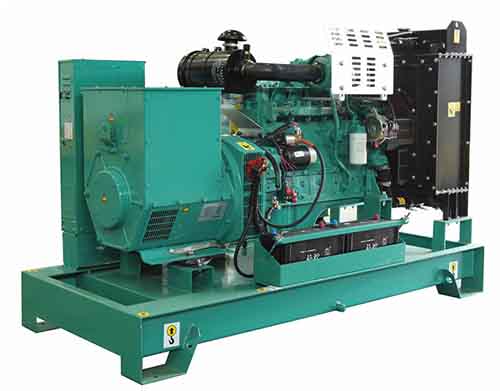

block diagram of a diesel generator set provides a simplified representation of the key components and their interconnections. It visually demonstrates how the diesel engine, alternator, control panel, and other essential elements interact to generate electrical power, ensuring smooth operation in power systems.

The design and optimization of a diesel generator set can vary depending on its complexity. Typically, it can take several weeks to months, considering the need for proper integration of the engine, alternator, fuel system, and electrical controls to ensure peak performance and efficiency.diesel generator set suppliers

The cost of a custom diesel generator set can range widely, typically from $5,000 to over $50,000, depending on factors such as capacity, brand, specifications, and additional features like noise reduction and fuel efficiency. High-quality components and installation will impact the total cost.

Tools such as load testers, digital multimeters, vibration analysis devices, and exhaust gas analyzers are essential for evaluating and optimizing the performance of diesel generator sets. Additionally, using software for real-time monitoring can help identify and address inefficiencies.

To maintain a diesel generator set, regular inspections, oil changes, fuel system cleaning, and cooling system maintenance are critical. Proper calibration of the control panel and routine performance checks are also essential for preventing costly breakdowns and ensuring reliability.

Improving fuel efficiency can be achieved by optimizing the generator load, ensuring proper maintenance of the fuel system, using high-quality fuel, and incorporating energy-saving technologies like variable speed drives and automatic load banks to manage fuel consumption effectively.

The block diagram acts as a roadmap for identifying the source of issues. By understanding the flow of energy and the function of each component, technicians can efficiently diagnose problems related to the diesel engine, alternator, or control systems, speeding up the troubleshooting process.

Best practices include clear labeling of each component, accurate representation of interconnections, and ensuring scalability for future upgrades. The block diagram should highlight safety features, fuel efficiency components, and ensure compliance with industry standards for electrical and mechanical systems.

The structure should be simple, using standard symbols for electrical components, with a logical flow that illustrates the diesel engine’s energy conversion processmain parts of diesel generator set. Key components like fuel tanks, exhaust systems, and cooling mechanisms should be easily identifiable, with attention to the operational sequence.

Block diagrams provide a high-level overview, making it easier for engineers to plan, maintain, and troubleshoot systems. They simplify communication between team members and facilitate the quick identification of problems, ensuring that the diesel generator set operates efficiently and with minimal downtime.